Two post lifts

Two-Post Lifts for Auto Repair Shops

In establishments engaged in automobile repair, whether it's a specialized auto service or a small repair shop, an essential piece of equipment is the two-post car lift. With the help of a car lift, your mechanics can easily access the internal components and hard-to-reach areas of the vehicle. Two-post lifts require no special maintenance and are easy to service.

Features of a Two-Post Lift

- Drive

- Synchronization

- Dimensions

- Construction

- Safety

- Installation

Drive of a Two-Post Lift

A two-post lift can have two types of drives: electro-hydraulic or electro-mechanical.

These lifts stand out for their energy efficiency, quiet operation, fast lifting and lowering with smooth motion, and safety. They consist of a motor with a hydraulic pump and two hydraulic cylinders. Hydraulic fluid circulates through special hoses.

Automotive two-post lifts with electro-mechanical drive have one or two electric motors that are installed on the columns, either at their base or on top. Some lifts are equipped with a single electric motor. In this case, the force from the column where the electric motor is mounted is transmitted to the second column using a chain or belt drive. In electro-mechanical lifts, particular attention should be paid to the "screw-nut" system. Daily inspection of the screw and nut for wear is necessary, as well as constant monitoring of the amount of lubrication to ensure it is neither excessive nor insufficient. In case of significant wear of the screw or nut, there is a high risk of the lifted vehicle falling or the lift not raising the vehicle at all.

Synchronization of a Two-Post Lift

Synchronization is an important differentiator for two-post lifts. For example, a lift with upper synchronization has limitations in lifting very tall vehicles. A lift with lower synchronization cannot service vehicles with very low ground clearance.

Upper Synchronization

As you have already understood, two-post lifts can have upper and lower synchronization. Upper synchronization can be either electro-mechanical or cable-type. A two-post lift with upper synchronization is more expensive and more convenient to use than a base lift; it allows servicing vehicles with low ground clearance but requires a higher installation space.

Lower Synchronization

Lower synchronization: cardan and cable type. There are also two-column lifts with electronic synchronization of the columns.

Dimensions

Two-post lifts from different manufacturers also differ in dimensions (width, height, length of arms, distance between columns, etc.), load capacity, and vehicle lifting height.

- H1 - Lift height.

- H2 - Lifting height.

- L1 - Lift width.

- L2 - Distance between columns.

- L3 - Arm length.

Construction of a two-post lift

Two-column lifts are divided into: Asymmetrical and Symmetrical by their construction.

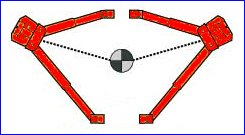

Asymmetrical construction

A lift with asymmetrical construction is used for servicing vehicles with a wide wheelbase. The columns in an asymmetrical lift are slightly turned towards the rear of the vehicle, and the arms have different lengths - the front ones are shorter. Asymmetrical automotive lifts are recommended for vehicles weighing up to 3 tons.

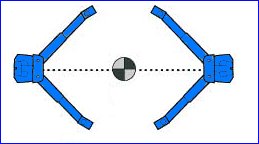

Symmetrical construction

A two-post lift with symmetrical construction provides greater stability for the vehicle on the lift arms, so such lifts are recommended for larger and heavier vehicles.

Spacers for a two-post lift

Some models allow for quick replacement of spacers and pads on the lift arms. Spacers of different lengths may be included with the lift or offered as an additional accessory.

Pads for the arms of a two-post lift

Safety

One of the main requirements for any lift is safety. There are models with automatic locking and unlocking of the lift arms or with manual operation. It is mandatory to have an emergency system, for example, in case of a power failure, and a safety valve to prevent overloading. Two-post lifts with upper synchronization have a lifting height limiter, which is important when lifting tall vehicles.

Installation of a two-post lift

Before installing a two-post lift, several important factors should be taken into account. One of these factors is the area on which the lift will be installed. When calculating the area, not only the dimensions of the lift itself should be considered, but also the dimensions of the serviced vehicles. Also, keep in mind that there should be ample space for the mechanic to work comfortably.

The second factor is a strong foundation. The foundation on which the lift is installed must meet very strict requirements. After all, the safety of work, ease of installation, and the strength of the entire structure depend on the foundation. To ensure easy installation and high reliability, the thickness of the foundation should be at least 15 cm (25 cm is recommended), and the concrete quality should be grade M300 or higher (for lifts with upper or electronic synchronization, M400 is recommended).

Important Note! You can install a two-post lift no earlier than 25 days after pouring the concrete. This is the time required for the concrete to harden and gain strength. Delivery and high-quality installation of a two-post lift can be performed by the service team of "Vell Craft" company.