Piston compressor Well Kraft WB-0.36/8

Description

Industrial High-Performance Compressor Well Kraft WB-0.36/8 with 135 Liter Receiver

High Performance and Reliability

The oil-lubricated compressor is equipped with a powerful and reliable electric motor of 3.0 kW, which easily handles high loads, thus positively impacting the compressor's service life.

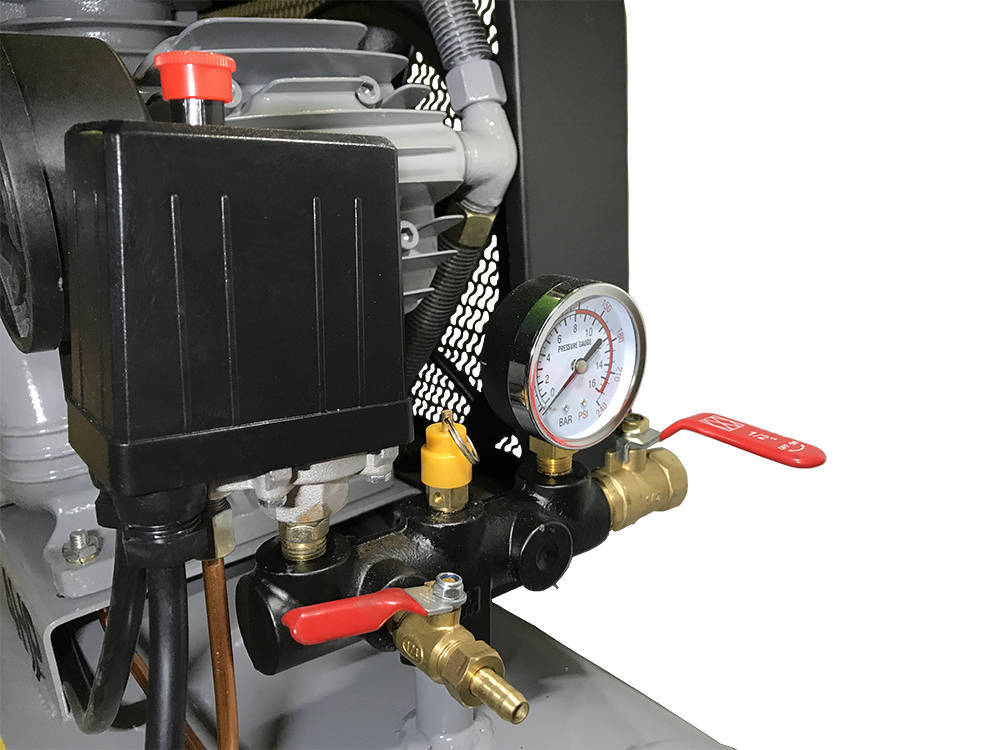

The unit is protected by uninterrupted, high-precision automation against excessive or insufficient pressure, electric motor overload, and excessive wear of the compressor unit due to overheating.

The compressor is available in two connection versions: 220V or 380V.

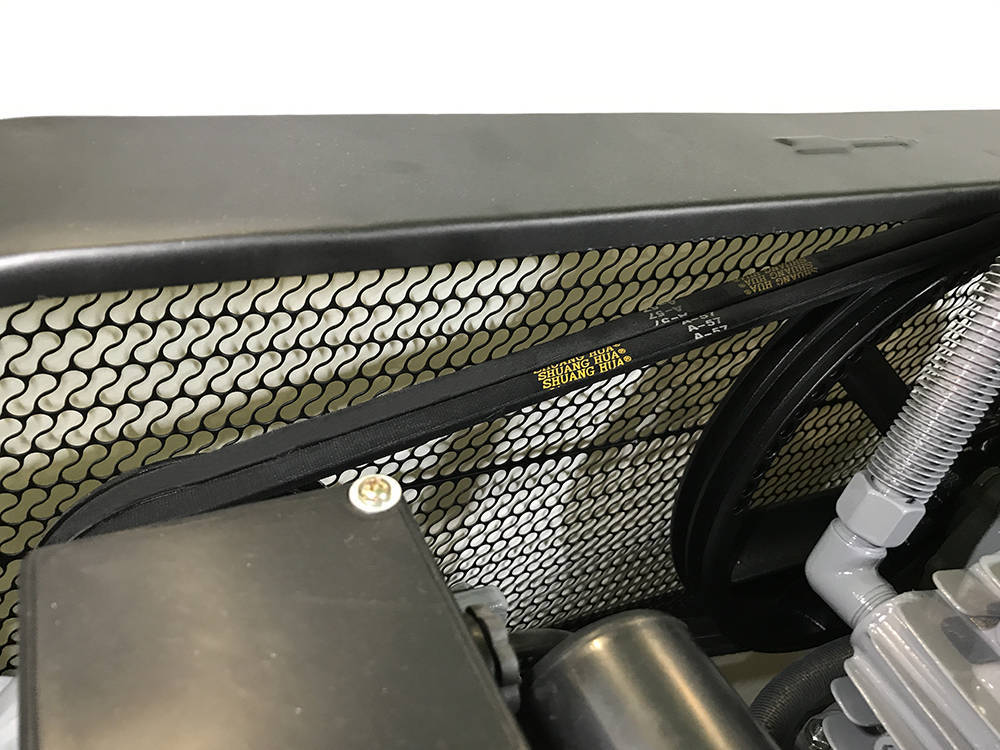

Double V-belt drive - This design solution makes the main unit faultless, significantly reduces noise, and minimizes sudden compressor stops, as the compressor continues to operate on the second belt if one breaks. High level of belt drive reliability - Piston seizure will not lead to motor breakdown, but only damage the belt.

The Well Kraft compressor is equipped with an oversized check valve, which positively affects its performance and ensures a smooth start.

Extended Operation and Excellent Cooling

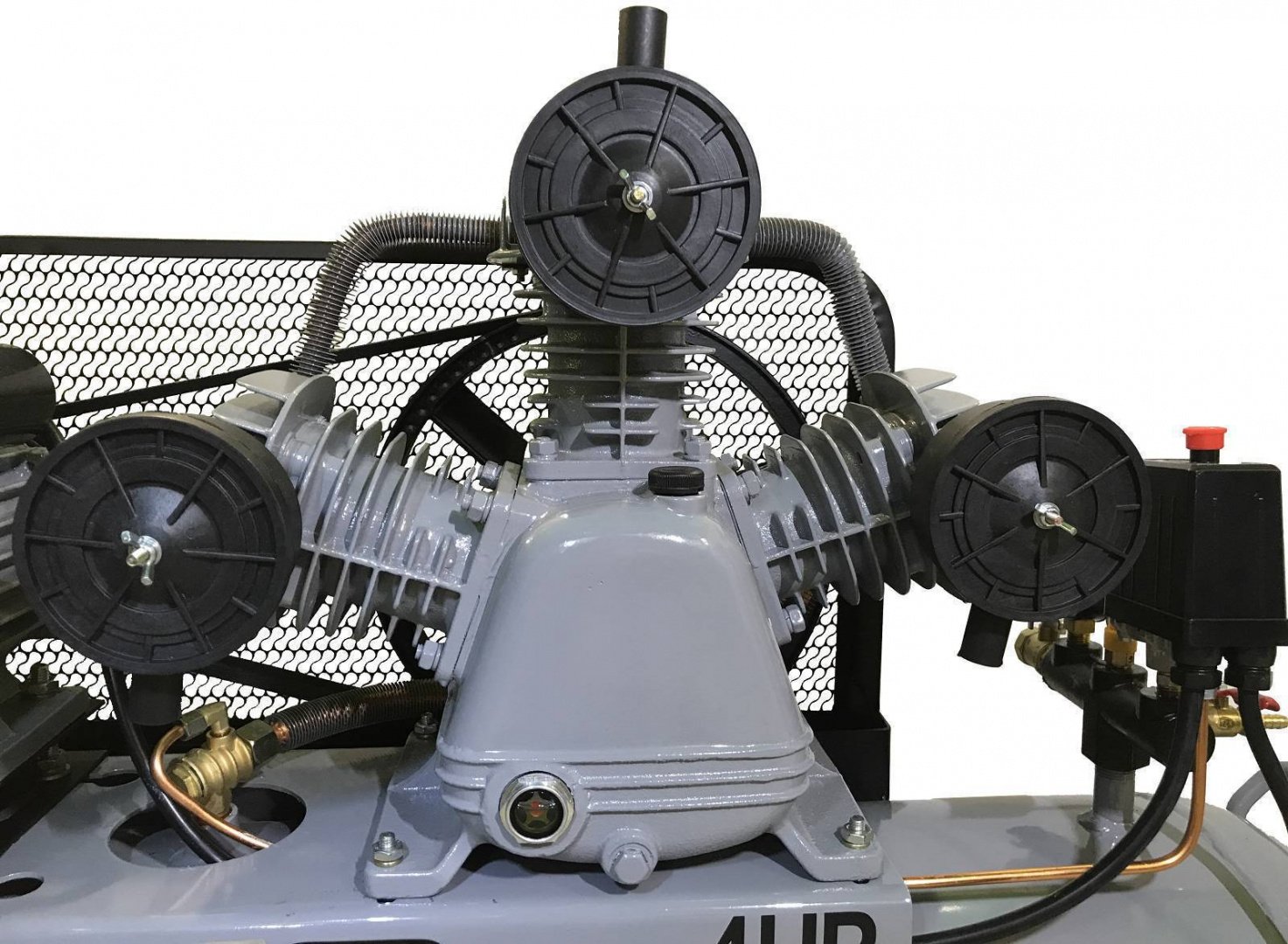

Cast iron heads and cylinder cover with cooling fins for optimal heat dissipation. Also, the spokes on the pulley are angled, creating an airflow that blows over the heads when the pulley rotates. This solution serves as additional cooling and protects the compressor unit from overheating.

Three pistons guarantee a continuous air supply without forced stops, allowing for stable operation of pneumatic systems. The impeller of the driven pulley and the electric motor pulley are protected by metal grilles. An oil level indicator is built into the compressor unit.

Three air filters - the compressor can be freely used for work in areas with high dust concentration. The filter elements perfectly cope with their task and have a long service life.

The Well Kraft compressor is equipped with two outlets for connection to the main pneumatic network and additional equipment. A built-in pressure gauge allows for air pressure control.

Despite its dimensions and weight, the compressor has sufficient mobility for convenient movement around the work site. Four large wheels and transport handles will allow you to freely move this unit.

Scope of Application

This industrial compressor is designed for use in repair, installation, and painting works, in auto repair shops, car services and service stations, tire fitting shops, and also in construction. Basically, such a compressor is used where a small amount of pneumatic equipment and pneumatic tools are required.

Inflation Drying Painting Water Spraying Car Washes

Another area of use for these compressor models is one of the directions of painting - airbrushing. To excel in this field, a certain taste, talent, an airbrush, and, of course, a device used to supply air to the airbrush - a compressor - are necessary.

Specifications

|

vendor code

|

012065 |

|

Supply voltage, V

|

220, 380 |

|

Engine power, kW

|

3 |

|

Air pressure, bar

|

8 |

|

Number of cylinders, pcs

|

3 |

|

Receiver volume, l

|

135 |

|

Productivity, l/min

|

450 |

|

Compressed air connection

|

No |

|

type of drive

|

Belt-driven |

|

engine's type

|

Electric |

|

Compressor type

|

Oil |

|

Receiver location

|

Horizontal |

|

type of instalation

|

Mobile |

|

Total height of the product, mm

|

850 |

|

The total width of the product, mm

|

480 |

|

Total length of the product, mm

|

1260 |

|

Warranty, months

|

12 |