Spray booth Termomeccanica GL1

- 6

- 6,75

- 7

- 7.5

- 8

- 8.25

Our qualified specialists will definitely help you.

Description

The GL1 Spray Booth painting and drying chamber is designed to solve any tasks in the field of repair painting. It allows working with any type of paint and varnish materials. For working with water-based materials, additional air blowers can be installed (optional).

GL1 Spray Booth Chamber

Internal dimensions:

- Length – 7000 mm;

- Width – 4000 mm;

- Height – 2800 mm.

Foundation:

The foundation with two recesses is built according to the drawings provided by the chamber manufacturer. Air intake through 2 rows of grates installed at floor level. The grates are made of galvanized iron, grate size 750 x 100 x 30 (height) mm, load 600 kg per wheel track. Frames for installing paint-absorbing filters are installed under the grates.

Galvanized grates:

Support grates are made of galvanized steel, dimensions: 750 x 1000 mm, height: 30 mm. Load per wheel track of 250 x 250 mm - 500 kg.

Panels:

Polyurethane panels with insulation (modular type with tongue-and-groove connection). Thermal insulation is provided by an insulating layer (DIN 4102) inside the panels. Average density: 40 kg/m3. Heat transfer coefficient: 0.35 kcal/m2c.

Entrance Gates

Three-leaf entrance gates: one gate leaf can be used as a personnel door. Large glass windows are located on all gate leaves, allowing observation of the processes taking place inside the chamber.

Lighting

The chamber is illuminated by lighting units (4 high-efficiency IRC 85 daylight lamps in each), located in the upper part of the side panels at an angle of 30°, which guarantees sufficiently uniform illumination.

The lighting units are a structure made of painted galvanized sheet metal, equipped with two plastic sockets, each supplying power to two electric daylight lamps. The bulbs are insulated from the drying zone by layered crystallized transparent plastic, manufactured in accordance with EU standard prEN 12600:2000.

Control Panel

BOARD 128: the electronic control unit is manufactured in accordance with all current standards. Enclosure protection degree IP54. The panel houses the chamber controls and thermoregulation, indicator lights showing active modes or functions, a timer, a thermostat, a time counter, an emergency stop button, a main switch, an operating mode selection button, and a burner on button.

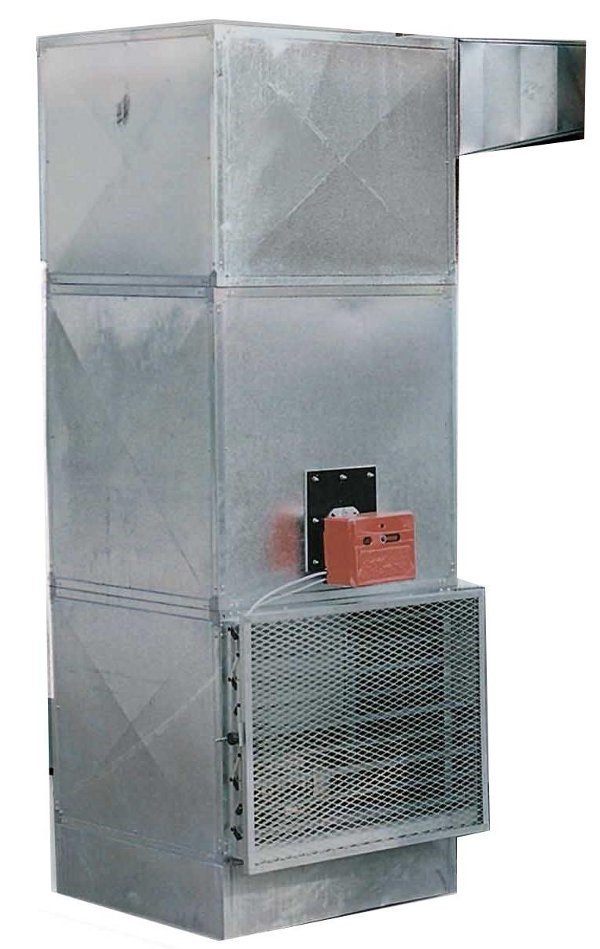

Generator

- Maximum thermal power of oil burner: 180000 kcal/h.

- Maximum temperature fluctuation range 7°/8°C. Has excellent thermal efficiency.

Air supply unit – this is a metal structure with a thickness of 12/10, made by bending metal sheets without heating and externally covered with galvanized steel. The structure is divided into compartments. There are special doors to provide access inside the unit for inspection and maintenance.

- Maximum thermal power: 180000 kcal/h;

- Air exchange: 22000 m3/h;

- Engine power: 7.5 KW;

- Set of inlet acrylic filters;

- Efficiency 80%-eu3;

- Automatic switching of painting/drying phases;

- Painting temperature: 20 - 25 °;

- Drying temperature: 50 – 60°;

- Noise level: 70 dB(A).

Exhaust

The support frame is made of 12/10 sheet iron, externally covered with galvanized metal sheets with insulation, which can be painted upon request. The exhaust unit includes an electric damper and a synthetic fiber filter system.

- Air exchange: 22000 m3/h;

- Engine power: 7.5 KW.

Filters

|

Ceiling filters:

|

Paint absorbing filters:

|

Accessories

Thermoregulator - this is a pyrometer located inside the control panel, the purpose of which is to set the required temperature during painting and drying modes.

Implemented PSC Projects

The Italian company Termomeccanica is one of the leaders in the production of painting equipment for service stations and car repair shops. Their products are supplied to many countries worldwide, thereby gaining the trust of customers. Termomeccanica products are manufactured in accordance with modern quality standards and have all the necessary certificates.

Termomeccanica GL is an Italian company that has been supplying equipment for various paint shops since 2003. Repair lifts, body straightening stands, specialized stations for welding aluminum panels and preparation stations for painting, booths for color matching laboratories, OSK, IR drying, spray gun washers – Termomeccanica produces at the highest Italian level.

The company has been manufacturing painting equipment and accessories for over 30 years, thus possessing extensive experience and customer trust.

The use of robotic technology ensures high accuracy of all production calculations and enables maximum optimization and organization of the workflow. All parts and components are produced directly at the Termomeccanica plant. This guarantees assembly quality and high performance of all equipment.

Specifications

|

vendor code

|

007934 |

|

Internal dimensions, mm

|

7.000x4.000x2.800 |

|

Base height, mm

|

30 |

|

Floor surface structure

|

Grates in 2 rows, Pit installation |

|

Insulation material

|

DIN 4102 |

|

Number of entrance gates, pcs

|

1 |

|

Quantity of gate leaves, pcs

|

3 |

|

Number of exhaust ventilation motors, pcs

|

1 |

|

Exhaust fan capacity, m3/h

|

22000 |

|

Exhaust ventilation power, kW

|

7.5 |

|

Poppy. thermal power of the burner, kcal/h

|

180000 |

|

Camera control system

|

Temperature regulator, Drying timer, Power indicator, Staining progress indicator, Drying stage indicator, Alarm indicator, Emergency switch |