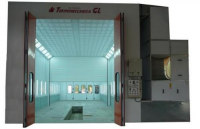

Spray Booth Powertherm 60°-80° SPRAY BOOTH Termomeccanica

- 6

- 6,75

- 7

- 7.5

- 8

Our qualified specialists will definitely help you.

Description

Painting and Drying Chamber Termomeccanica POWERTHERM 60° -80° SPRAY BOOTH

Used for professional automotive refinishing. The design incorporates a semi-exhaust fan, which allows for the most effective cleaning of the chamber from accumulated waste during painting operations.

Used for professional automotive refinishing. The design incorporates a semi-exhaust fan, which allows for the most effective cleaning of the chamber from accumulated waste during painting operations.Construction

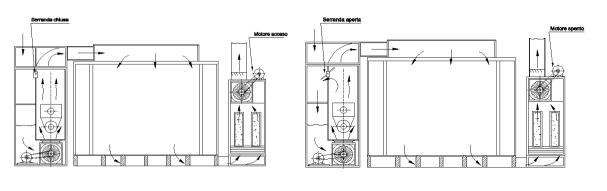

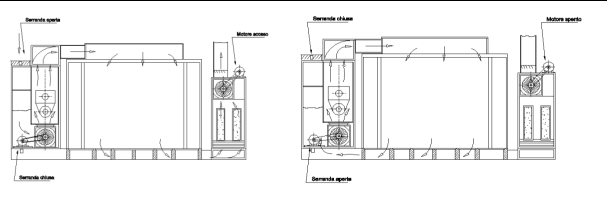

The design is a modular block of bent panels, filled with polyurethane filler, 40 mm thick, and painted white. The chamber set includes protective filters made of fire-resistant material. Depending on its dimensions, the chamber is equipped with an engine ranging from 5.5 kW to 11 kW. The system features an aggregate suction unit with full air circulation.

Equipped with three-leaf entrance gates, one leaf of which can be used as a personnel door. All gate leaves have large glass windows that allow observation of the ongoing processes inside the chamber. The ventilation and heating system consists of a stainless steel water heater and a Riello burner with a capacity of 180,000 kcal/h.

The kit includes a thermostat with a sensor for temperature regulation in the chamber, as well as a safety thermostat (in case the temperature threshold is exceeded).

Filtration

Exhaust fumes are discharged through the rear of the chamber. The air supply velocity is 0.25 m/s. Exhaust air is removed using 2 rows of grates with frames and paint filters. The ceiling filter is illuminated by two rows of fluorescent neon ceiling lights angled at 30°. The air regulation damper is manually adjusted for the spraying and baking phases.

Control Panel

The semi-automatic electrical control unit manages: light adjustment, engine operation, and burner. The panel features chamber controls, indicator lights showing active modes or functions, a timer, a time counter, an emergency stop button, a main switch, and an operating mode selection button.

The kit includes a thermostat with a sensor for temperature regulation:

The kit includes a thermostat with a sensor for temperature regulation:- Thermostat complete with temperature regulation sensor

- Generator

- Safety solenoid valve

- Minimum and maximum pressure relays (pressure sensors in case of malfunction)

- Safety thermostat (in case of exceeding the temperature threshold)

Basic equipment:

| Max. thermal power of burner, kcal/h | Exhaust ventilation power, kW | Mineral wool panels, kcal |

| 180000 | 5.5 | 6000x4000 |

Available options for equipping the painting and drying chamber:

| Max. thermal power of burner, kcal/h | Exhaust ventilation power, kW | Mineral wool panels, kcal |

| 250000 | 11 | 6750x4000 |

| 340000 | - | 7000x4000 |

| 4200000 | - | 7500x4000 |

| - | - | 8000x4000 |

The Italian company Termomeccanica is one of the leaders in the production of painting equipment for service stations and car repair shops. Their products are supplied to many countries worldwide, thereby gaining the trust of customers. Termomeccanica products are manufactured in accordance with modern quality standards and have all the necessary certificates.

Termomeccanica GL is an Italian company that has been supplying equipment for various paint shops since 2003. Repair lifts, body straightening stands, specialized stations for welding aluminum panels and preparation stations for painting, booths for color matching laboratories, OSK, IR drying, spray gun washers – Termomeccanica produces at the highest Italian level.

The company has been manufacturing painting equipment and accessories for over 30 years, thus possessing extensive experience and customer trust.

The use of robotic technology ensures high accuracy of all production calculations and enables maximum optimization and organization of the workflow. All parts and components are produced directly at the Termomeccanica plant. This guarantees assembly quality and high performance of all equipment.

Specifications

|

vendor code

|

013561 |

|

Wall panel thickness, mm

|

40 |

|

Insulation material

|

Polyurethane |

|

Number of entrance gates, pcs

|

1 |

|

Quantity of gate leaves, pcs

|

3 |

|

Exhaust ventilation power, kW

|

5.5-11 |

|

Burner model

|

Riello |

|

Poppy. thermal power of the burner, kcal/h

|

180000 |

|

Total height of the product, mm

|

2500 |

|

The total width of the product, mm

|

4000 |

|

Total length of the product, mm

|

6000 |