Hydraulic Workshop presses

Hydraulic Press for Car Service

A hydraulic press is mainly used in locksmith and assembly sections for:

- pressing out bushings and plain bearings

- straightening body elements

- stamping parts

- pressure gluing

Among the technical characteristics of a hydraulic press, the main one is its force, usually they are divided into: 5, 10, 12, 15, 20, 30, 40, 50, 75, 100, 150 and 200 tons. Hydraulic presses with a force of up to 15 tons are used for minor repairs, for normal car service work it is better to take a press with a force of 15 tons or more. If you are going to service trucks or specialized equipment, it is better to take a press with a force of 40 tons or more.

Classification of Hydraulic Presses

Hydraulic presses are:

- With manual drive

- With pneumo-hydraulic drive

- Electro-hydraulic

Hydraulic presses with a manual drive are driven by the muscle power of the operator (master). Due to its low price, this type of hydraulic press is considered the most popular and is most often used in garage workshops. Hydraulic pumps in manual hydraulic presses are produced with 1 or 2 plungers. In modifications with 2 plungers with different flow capacities, it is possible to regulate the speed of the press.

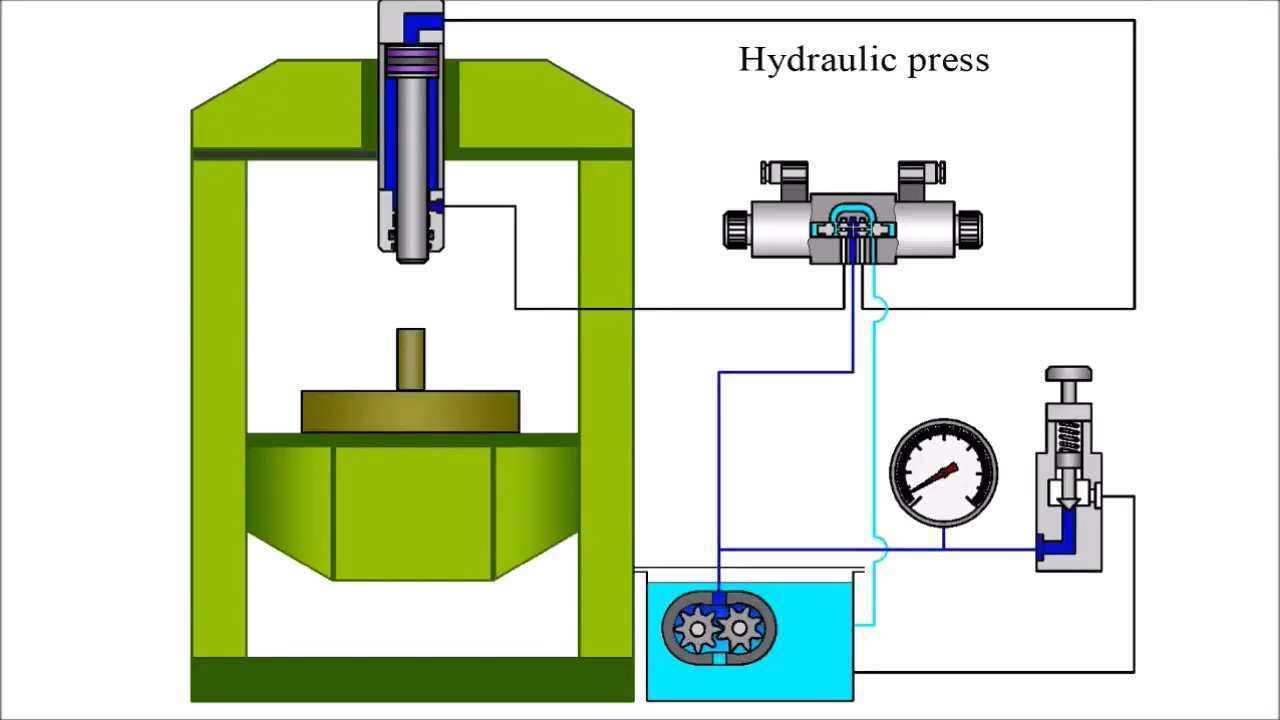

The basis of a hydraulic press is a collapsible structure made of racks, beams, and a hydraulic drive. A large base and a welded structure provide maximum stability during operation. The press frame has a number of precise holes necessary for vertical movement and fixing the press's work table at the required height.

The force on the piston is created by a manual hydraulic pump. It provides a smooth and uniform force. A manometer is installed on the upper part of the press to control the pressure.

To use a hydraulic press with a pneumo-hydraulic drive, you will need to connect a pneumatic compressor, which leads to large material costs. Such presses are produced with 1 or 2 plunger pairs, models with a pneumo-hydraulic pump are 30-40% more expensive.

Pneumo-hydraulic press is designed for pressing in and pressing out bushings, bearings or for manufacturing pressed parts. These parts are formed by pressing under very high pressure, while applying little effort.

The press has a manual + pneumatic drive that builds up pressure, and a movable working piston. A large base and a welded reinforced structure ensure maximum stability during operation. The press frame has a number of precise holes necessary for vertical movement and fixing the press's work table at the required height.

A reliable hydraulic system with a pressure gauge provides smooth, uniform force. A safety valve protects the press from breakage due to overload of the working pressure.

In electro-hydraulic presses, a plunger pump, under the influence of an electric motor, creates pressure in the hydraulic cylinders. Such presses are significantly more expensive than those discussed earlier.

In everyday use of the press, especially when working with bushings and bearings, the function of returning the rod to its original position is very convenient. A spring attached to the press frame returns the rod to its original position when the pressure decreases.

By purchasing a hydraulic press from us, you get a guarantee of high-quality equipment and a prompt solution to any issues that arise, thanks to our service department and a warehouse of spare parts.